Nanocs

polymer-based nanodiamond coating and applications

Nanocs

innovates a unique technology to produce the hard carbon film consisted of

nanocrystalline diamonds in amorphous carbon matrix from a special

diamond-like polymer precursor. The polymer precursor is easily soluble

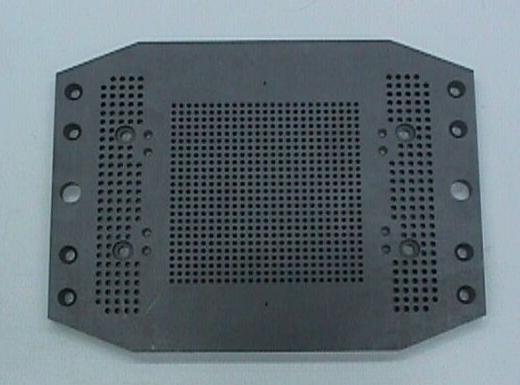

in organic solvents, and can be applied to various substrates by

spinning, dipping, draining, brushing or printing. The films can be

coated on complex shape with large area both inside and outside

simultaneously. By a heat-treatment, the polymer precursor can be

converted into hard carbon film which has excellent mechanical and

wear properties. Currently, our hard carbon films have been used as

graphite coating for the heat-corrosion and wear-resistant films, such as

moulds, electrodes, extruders and cylinders, as ceramic coating to

enhance surface hardness and wear resistance for tools application in

milling, cutting, boring; bearings, dice, rollers.

Comparison of the mechanical and wear properties of graphite, normal

CVD hard-carbon on graphite and Nanocs

hard-carbon on graphite.

The hardness of the Nanocs hard carbon

film coated on graphite can be enhanced 20-50 times compared to graphite, 2-5 times

compared to normal CVD hard carbon film coated on

graphite. The wear resistance property and life time of the Nanocs

hard carbon film coated on graphite can be enhanced significantly (above

100 times), comparing with graphite or normal CVD hard carbon film

coated on graphite.

Nanocs

polymer-based nanodiamond coating

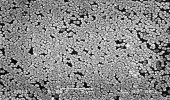

Structure and Morphology:

The hard carbon film converted from polymer precursor consists of

diamond crystals and amorphous carbon matrix.

Mechanical property:

The hardness and Young's modulus of the hard carbon films were

determined by a Nanoindenter using continuous stiffness measurement. The hardness and Young’s modulus of Nanocs

hard carbon film on graphite is about 9 and 120 Gpa, respectively, while the hardness and Young’s modulus of graphite substrate is about

0.25 and 3 GPa. For CVD hard carbon film on graphite, the hardness and

Young’s modulus is 2.5 and 30 Gpa, respectively. Nanocs hard carbon film

coated graphite is much higher than that of the graphite substrate or

normal CVD hard carbon coated graphite.

The hardness and Young’s modulus of Nanocs

hard carbon film on Si3N4 ceramic substrate is

about 28 and 340 Gpa, whilst the hardness and Young’s modulus of Si3N4

ceramic substrate is about 9 and 240 Gpa, respectively. Clearly, Nanocs

hard carbon coating can enhance the surface hardness of the ceramic

significantly.

Contact: info@nanocs.com

for more information!